In the fast-moving world of screen printing, adaptability is key. Whether you're running a small shop or managing multiple presses, the tools you use can either hold you back or push you ahead. Bison Platens are designed for shops that want more freedom, more value, and more versatility — without sacrificing durability or performance.

Smarter Construction for a Smarter Shop

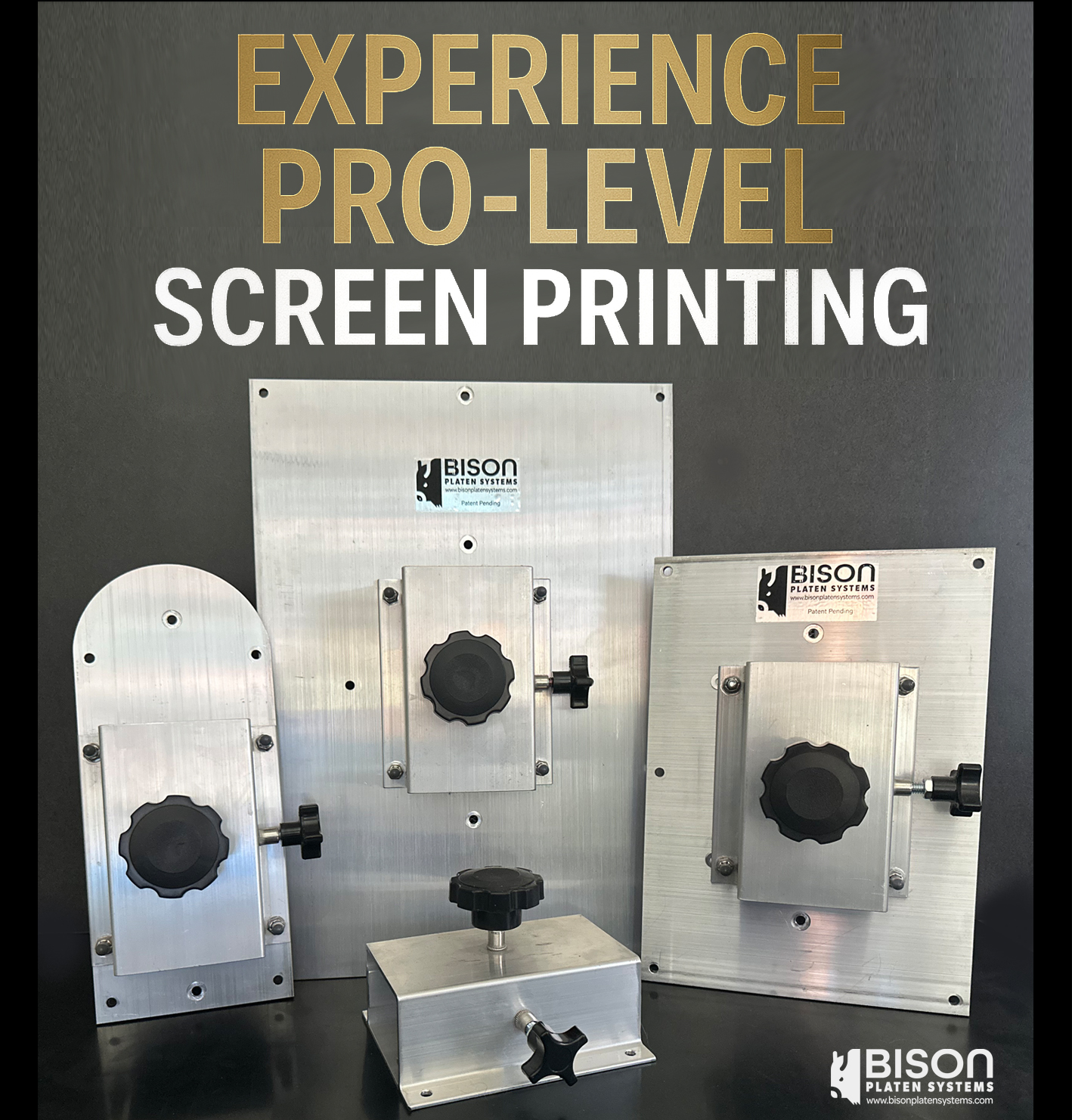

Traditional all-aluminum platens are rigid, heavy, and expensive to modify. Need a different size or print location? That usually means buying an entirely new platen. With Bison Platens, you get the best of both worlds:

- A solid 1/4-inch aluminum base plate that delivers the flatness and consistency required for quality prints.

- Customizable top plates made from cabinet-grade plywood that can be swapped out quickly and affordably.

This means you can switch between sizes and styles without buying new platens every time. It’s a modular approach that scales with your business.

Built to Withstand, Designed to Adapt

Where other systems rely on adhesive tape to bond components, Bison Platens are securely bolted for long-term durability. The result? A platen that stays flat, resists heat warping, and performs reliably across countless print cycles.

Cost-Efficient Without Cutting Corners

Why pay premium prices for rigid aluminum platens that offer no flexibility? With Bison, you invest once in a strong aluminum base and swap out only the affordable top layer as needed. This means:

- Lower costs over time

- Less storage space for rarely-used platens

- Faster response to custom job requests

Ready for Custom Jobs on the Fly

Sleeves, pant legs, youth garments, tote bags — custom orders that used to slow down production now fit right into your workflow. Bison’s customizable top plates make it easy to print in any location or on any item without added downtime or expense.

The Platen Built for the Future

The screen printing industry is evolving fast, and shops that can adapt will thrive. Bison Platens let you take on more jobs, offer more services, and stay one step ahead of the competition — all while keeping your gear lean and your costs under control.

Conclusion

Don’t let outdated gear hold you back. Whether you're printing for schools, events, businesses, or custom clients, Bison Platens are the smarter, more adaptable solution.

Break free from limitations. Print smarter with Bison.